Features

◆Simple but reliable structure; low operation costs

◆High crushing efficiency, flexible capacity and energy conservation

◆With fine crushing and coarse grind functions

◆Materials’ moisture content has little influence. Moisture content could be up to 20%.

◆The impeller and the crushing cavity are lined with the materials, considerably reducing the wear of components and maintenance load.

◆Convenient operation, maintenance and overhaul

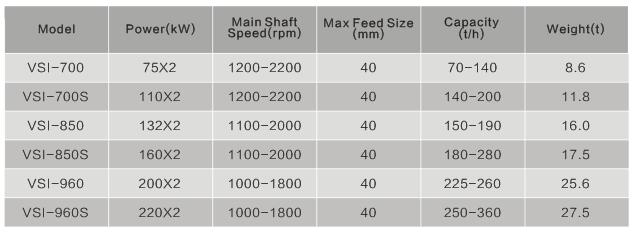

Technical Parameters

Applications

Aggregate Production

In the production of aggregate and artificial sand, end products are usually required to meet the local construction standards. VSI vertical shaft impact crusher is capable of shaping the aggregate and producing artificial sand in good shape to meet the construction standards and reduce waste.

Fine Crushing Operation

VSI vertical shaft impact crusher can be applied to the concentrator for the production of mill feed materials or heap-leaching materials less than 6mm, especially applicable to the crushing of wet sticky materials.

Mill Feed Materials

VSI vertical shaft impact crusher can produce mill feed materials, that is, it can be used as an additional fine crushing equipment or replace the rod mill. When applied to the mill feed materials in lime or cement plants, VSI can bring the mill feed size from 25mm down to 5mm, improving 25% mill capacity and saving 15% energy.

Prior Crushing

VSI is able to crush the brittle materials first, which can be used in the crushing of mixed materials, extraction of valuable minerals from the waste. For example, crush the impurities attached to the garnet; or remove other soft materials on the surface of gravel, like shale and lignite.

Dispersing Function

VSI can break up the bulk materials after the high pressure roller mills to produce more useful materials.