Brief Introduction

Our company is able to independently produce C series European jaw crusher. We introduce some foreign technology, on the basis of field experience from customer sites, to optimize the cavity design. Model P160 has the maximum feed opening: 1200mm*1500mm, while most of the domestic manufacturers are too far behind to catch up with us. The adoption of pinned and bolted steel structure and floating installation enables longer service life and lower failure rate of this crusher which is widely used in large sand and stone plants.

Advantages of C Series European Jaw Crusher over Common Jaw Crusher

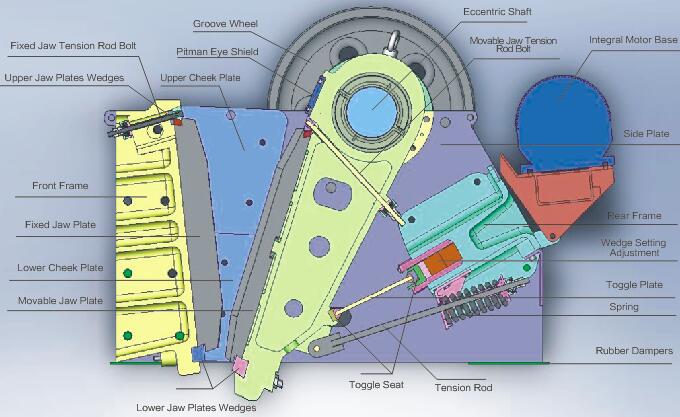

◆The pinned and bolted steel structure effectively absorbs the dynamic forces thus reducing the dynamic loads transmitted to the frame underneath to effectively solve the problem that ordinary frame is easily broken.

◆The floating installation (rubber dampers and stoppers mounting) plays an important role in the protection of eccentric shaft, bearings and movable jaw, leading to 30%-40% longer service life of those parts compared to any common jaw crusher.

◆On-board integral electrical motor base enables quicker and more convenient belt adjustment, saving 15%-20% energy.

◆The wedge setting adjustment system enables quicker and more convenient CSS adjustment and tightening, merely 3min-5min for every adjustment.

◆With one-station consistent grease lubrication system, it takes only 10 minutes per day to force the grease needed into the whole machine.

◆Each bearing is equipped with temperature sensor, timely warning to protect the bearing from burning.

◆The optimized V-shaped crushing cavity design increases about 20%-30% capacity, compared to the common jaw crusher.

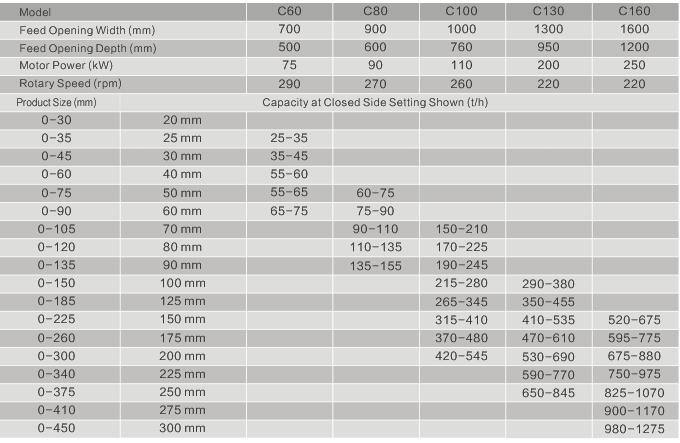

Capacity & Technical Parameters