Brief Introduction

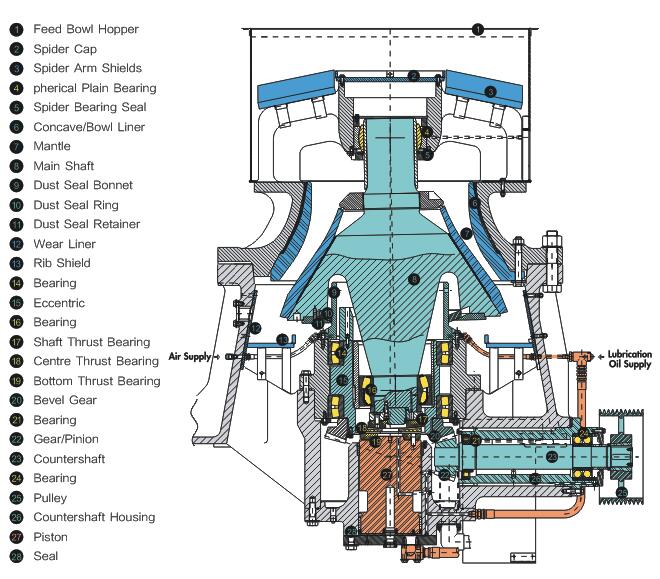

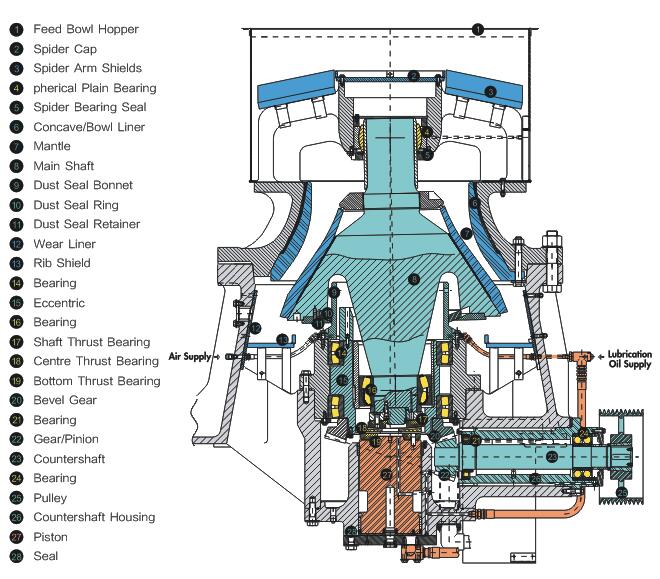

◆With human-oriented design, hydraulic pressure adjusts the discharge setting by push-button control, saving both labor and trouble, achieving step-less adjustment with high controllability in addition.

◆Single cylinder hydraulic pressure adjusts the discharge setting by the floating of the main shaft, head and frame and solves the problem that side cylinders and upper frame tilt to damage the main frame.

◆Hydraulic pressure adjusts the working pressure automatically. Once the materials over the crushing pressure inevitably enter the crushing cavity, the pressure regulating system will work and start pressure relief protection to enlarge the discharge setting automatically, letting out those materials hard to be broken to protect the equipment.

◆Easy to replace the wear parts. To save the time for worn parts replacement, with careful design and process, the joint faces between mantle and head are stably and firmly joined without any filling, saving both time and money on cleaning and filling the stuff. So does the bowl liner.

◆Low working pressure of hydraulic pressure leads to relatively low working pressure of the whole hydraulic system (not belonging to high pressure hydraulic system), reducing the stress on the hydraulic components and the main frame. Hydraulic system is more durable and stable, increasing the confidence.

◆Easy and quick assembly and transportation. With an advanced and effective design, the volume and weight of this model are relatively small, having few requirements for lifting, transportation, components replacement and maintenance.

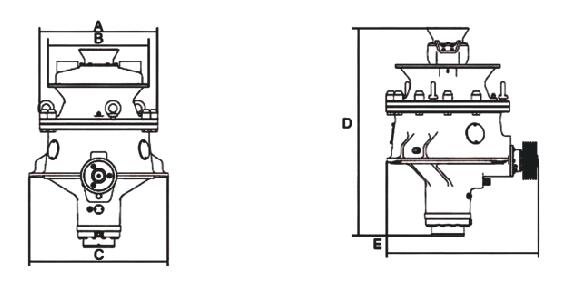

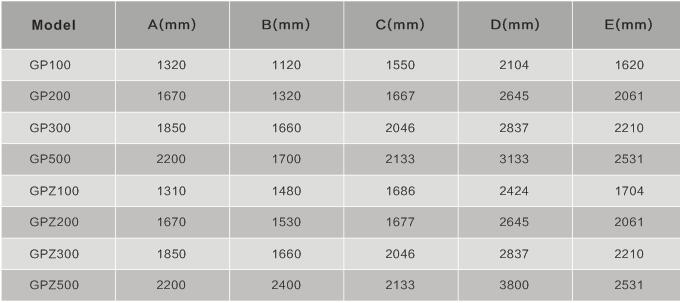

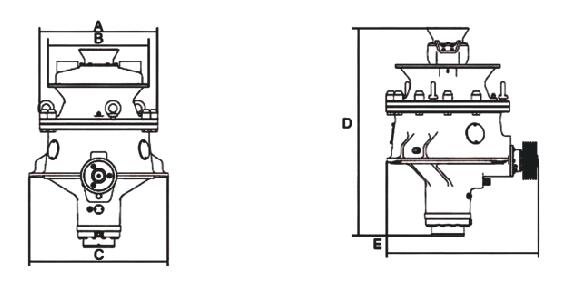

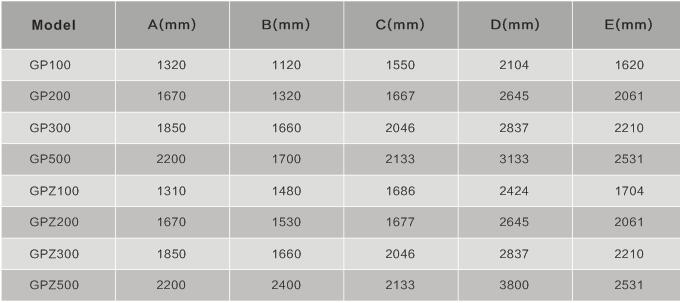

Overall Dimensions