Brief Introduction

Wet process widely used in artificial sand production line nowadays usually has the problem of heavy loss of fine sand (smaller than 0.16mm), even more than 20% sand loss, which leads to not only lower capacity but unreasonable gradation and coarse degree of fineness, decreasing the products quality and resulting in environment pollution.

To solve sand loss problem during the washing process, our company has developed WS series fine sand recycling system, which introduces foreign advanced technology and combines the actual application. It is widely used in the aggregate processing system of hydroelectric projects, glass raw materials processing system, artificial sand production line, coarse coal recovery in coal preparation plants, environmental engineering, etc, effectively solving the problem of fine sand recycling.

Features & Advantages

◆Polyurethane vibrating screen has longer service life and is uneasily blocked.

◆Polyurethane inner liner of the cyclone improves the service life of the whole equipment, helping achieve successful concentration and clarification of slurry.

◆Capability of recycling 85% fine materials wins massive superiority in technology and economy.

◆Full recycling of fine materials reduces the load of sedimentation tank and lowers the cleaning cost.

Working Principle

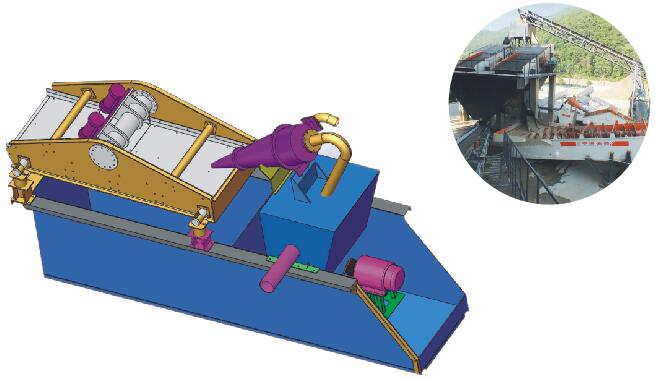

The slurry pump transports the slurry to the cyclone, fine sand centrifugally classified is sent to the vibrating screen by the sand-settling device, then sand and water are effectively separated after vibrating screen dehydration. Through the recycling tank, a little fine sand and mud return to washing tank again, and are discharged when the washing tank overflows. The weight concentration of the materials recycled by the linear vibrating screen is 70%-85%. Adjust the degree of fineness by changing the rotary speed of pump, slurry concentration, overflow volume and replacement of sand-settling device, fulfilling its three functions of washing, dehydration and grading.

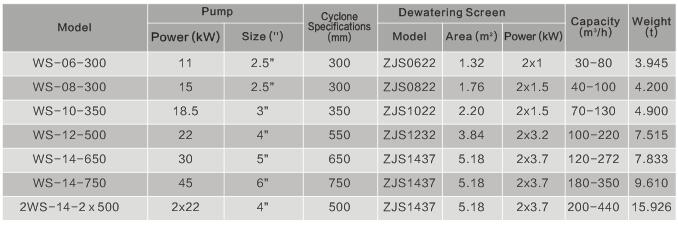

Technical Parameters